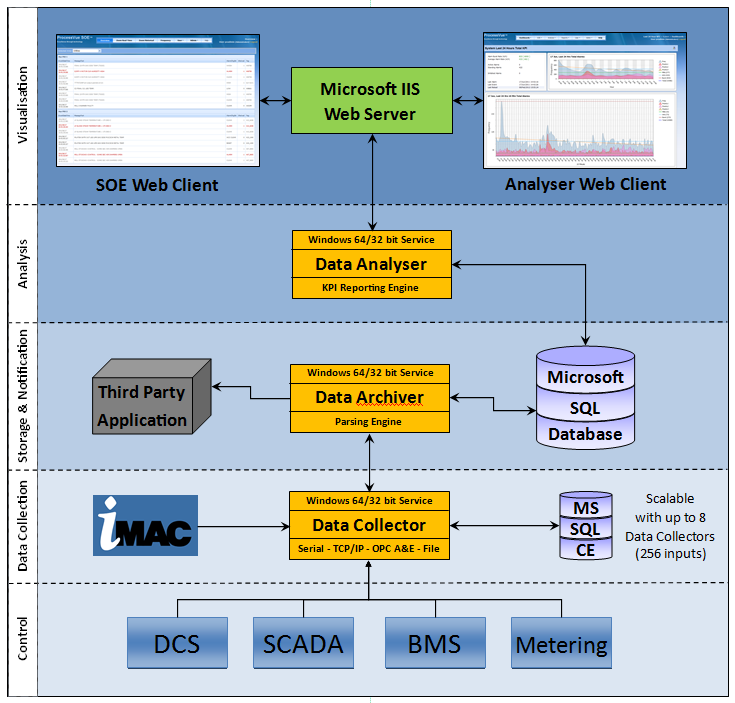

Data Collector

The Data Collector is designed to connect to a multitude of current and legacy control systems. The Collector runs as a Microsoft Windows Service and collects data from the following input types:

- - RS232 with specific drivers developed for Honeywell, Foxboro IA systems and the ability to create intelligent responses for time critical data handshaking.

- - TCP/IP - ProcessVue acts as a Generic/Text Only printer on your network capturing messages as they are printed.

- - File Monitor - Text and CSV.

- - OPC A&E which is widely used by SCADA and DCS vendors world-wide.

- - ProcessVue can connect to IMAC and capture the Data it has stored over the years.

Data Archiver

The Data Archiver is designed to connect to all Collectors and parse (convert complete strings into individual fields) the incoming data for writing to the SQL Database. In addition to this the Archiver has a multitude of additional features designed to manipulate the parsed data and add real value to the basic alarm string. A few of these features include:

- - Powerful and flexible parsing engine

- - Create rules for Alarm pattern recognition (IEC 61850)

- - ODBC Push to other Databases / Applications

- - Duplicate message handling

- - Look-up Table function to add additional information to messages from Excel files

- - Full and advanced error log

- - Email notification system

SOE Web Client

Coupled with a Data Collector and an Archiver, the SOE (Sequence of Events) Web Client provides the user access to the data being collected and tools to search filter and export that data. The SOE Web client also includes an advanced Frequency Analysis tool which quickly highlights bad actors. This client is designed for those customers who just need to collect, store and search alarm data or just need a printer replacement system.

Data Analyser & Web Client

ProcessVue Analyser is built from two software components, the Analyser Service and Web Client which enhances the analysis and reporting capabilities of ProcessVue to include EEMUA 191 based KPI reports. Analyser expands upon the the existing ProcessVue database allowing it to be easily added to an existing system. Analyser adds the following functionality to the ProcessVue system:

- - EEMUA 191 based KPI reports.

- - Real-time Dashboards and Reports.

- - Enhanced Frequency Analysis engine.

- - Automated report system.

- ProcessVue scales from a standalone alarm logging / printer replacement package to a company wide fully distributed system. Using the latest .NET technology from Microsoft, compatibility with both today's and future operating systems is ensured. An industry standard SQL Database ensures reliable, secure, expandable and portable data storage.

- A 64 or 32 bit Service oriented architecture means super fast performance on even the largest datasets. Services use store and forward technology over TCP/IP ensuring data integrity is maintained even when a LAN or WAN connection is unavailable.

- The latest Ajax 'Zero Footprint' web client technology means great performance whilst maintaining simple secure roll out over almost any IT infrastructure. All the latest web browsers are support from IE 6 to IE 10, Chrome, Firefox and even Safari.

- Connectivity to 3rd party applications and systems can be made simple using the very flexible re-constructor module to send data via TCP/IP port or ODBC.

- ProcessVue is VMware friendly. Together, ProcessVue and VMware offer simplified deployment and low operational costs, allowing customers to implement a flexible and scalable platform.